Kusunga aPallet Jackndizofunikira pakuwonetsetsa bwino ntchito zosalala komanso zothandiza m'magulu osungiramo zinthu, mafakitale, ndi makonda ena ogulitsa mafakitale. Pakati pa ntchito zofunika kwambiri, kukonza malo oyenera mafuta ndikofunika. In this comprehensive guide, we'll delve deeper into the importance of oil maintenance for pallet jacks and provide detailed steps on how to refill the oil to keep your equipment in top condition.

Kufunika Kwa Kukonza Mafuta:

1. Ntchito zosalala: hydraulic system ya pallet Jack imadalira mafuta kuti azigwira bwino ntchito. Adequate oil levels ensure smooth and effortless lifting and lowering of the forks, contributing to increased productivity and efficiency in material handling tasks.

2. Prevention of Damage: Insufficient oil levels can lead to increased friction and wear within the hydraulic system components, potentially causing damage or premature failure. Kukonza mafuta nthawi zonse kumathandizira kupewa kukonza ndalama komanso nthawi yopuma.

3. Chitetezo: Kusunga bwino kwa Pallet ndizotetezeka kuti mugwiritse ntchito. Ensuring the correct oil level reduces the risk of malfunction or unexpected failures that could pose safety hazards to operators and nearby personnel.

4.Ndipo kukwaniritsidwa kwa 4.Ndiponi Jacks okhala ndi Melet ali ndi moyo wautali. Mwa kuyang'ana pafupipafupi ndikuyika mafuta, mutha kukulitsa zida zanu ndikukulitsa kubweza kwake pa ndalama.

Kuwongolera kwapadera pokonza mafuta a Pallet Jack:

1. Sonkhanitsani zida zofunika:

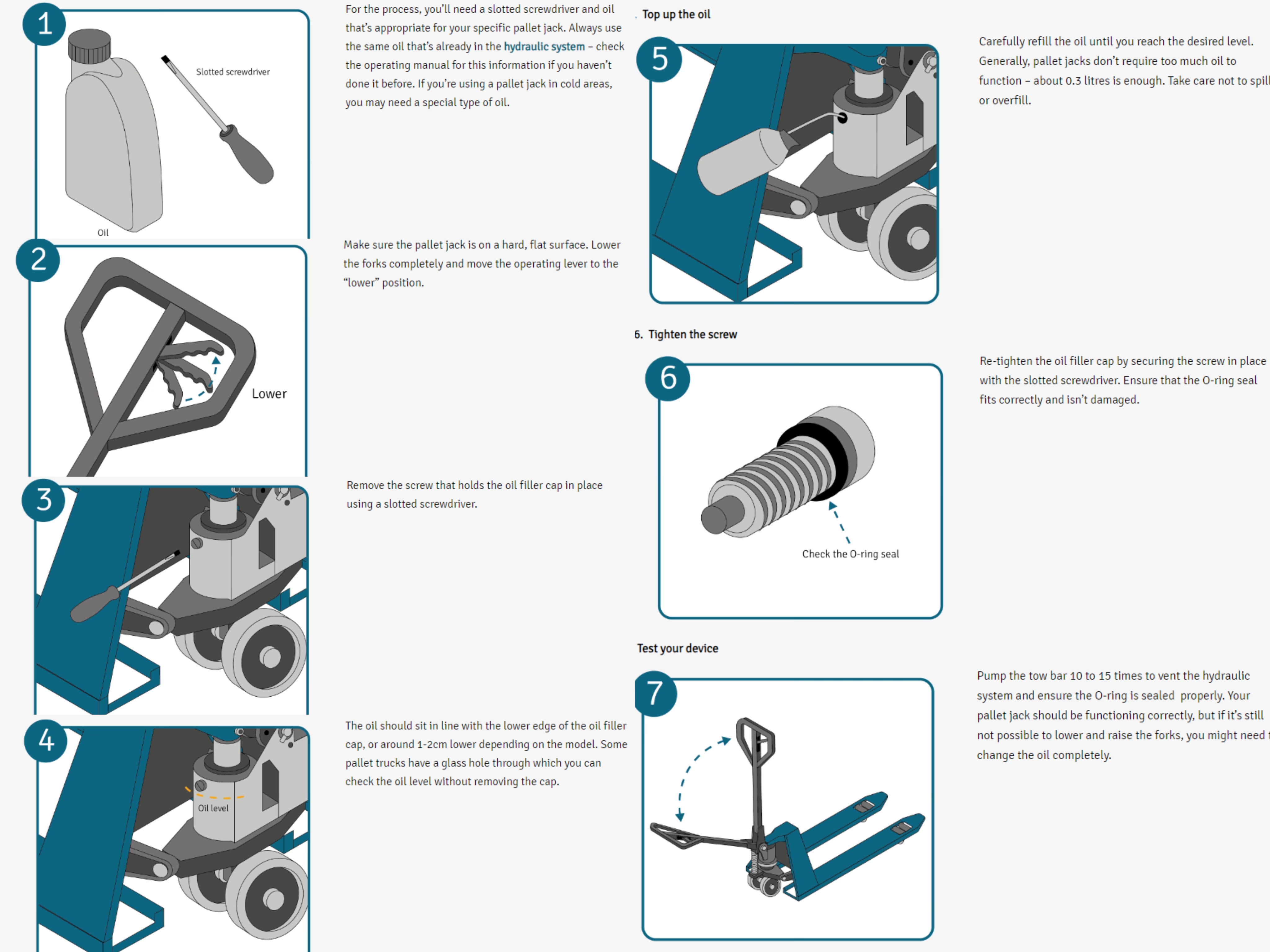

Asanayambe mafuta am'mafuta, onetsetsani kuti muli ndi zida zofunikira ndi zida zomwe zayandikira. Mufunika screwdriver yotsika ndi mafuta oyenera pa pallet pallet. Fotokozerani buku logwiritsira ntchito kuti mudziwe mtundu woyenera wa mafuta pazithunzi zanu.

2. Konzani pallet Jack:

Ikani pallet Jack pa zolimba, yosanja kuti muwonetsetse kukhazikika panthawi yokonza. Tsegulani mafoloko kwathunthu ndikukhazikitsa lever yolumikizira "yotsika" kuti isunge zovuta zilizonse mu hydraulic system.

3. Kufikira Phatikizani Mafuta:

Gwiritsani ntchito screwdriver yotsekedwa kuti muchotse screw yomwe ikugwira mafuta a mafuta m'malo mwake. Kwezani mosamala chipewa kuti mupeze mafuta osungira mafuta.

4. Onani kuchuluka kwa mafuta:

Ndi mafuta a filler capta adachotsedwa, yang'anani gawo lamafuta mu malo osungira. Mafuta ayenera kukhala pamzere wotsika ndi m'mphepete mwa chipewa kapena pafupifupi 1-2cm pansipa, kutengera ndi pallet Jack. Ma Jacks ena a Pallet amatha kukhala ndi zenera lowonekeratu la kuwonera kwa mafuta.

5. Ikani mafuta:

Ngati mulingo wamafuta ali m'munsimu yolimbikitsidwa, kutsanulira mosamala mu mafuta oyenera kuti mufikire mulingo womwe mukufuna. Pewani zolimbitsa thupi, chifukwa izi zimatha kuchititsa kuti anthu azithana ndi vuto la hydraulic. Nthawi zambiri, kuwonjezera pafupifupi 0,3 magetsi a mafuta ndikokwanira kwa ma Jalt ambiri.

6. Sungani kapika yamafuta:

Once the oil has been topped up, reposition the oil filler cap onto the reservoir and secure it in place by tightening the screw with the slotted screwdriver. Onetsetsani kuti mphete ya O-mphesa imayikidwa molondola komanso yosasinthika kuti ipewe kutaya mafuta.

7. YesaniPallet Jack:

To ensure proper sealing and functionality of the hydraulic system, pump the tow bar 10 to 15 times to vent any trapped air and distribute the oil evenly. Yesani Jack Jack potsitsa ndikukweza mafoloko kangapo kuti mutsimikizire ntchito yosalala.

By following these steps and incorporating regular oil maintenance into your pallet jack maintenance routine, you can ensure optimal performance, longevity, and safety of your equipment. Kumbukirani kupanga macheke ndi mafuta a mafuta monga momwe amafunikira kuti pakhale pallet jack yanu pachiwopsezo kwa zaka zikubwerazi.

Kuonjezera zokumana nazo:

Last year, while overseeing warehouse operations, I encountered a situation where one of our pallet jacks started experiencing difficulty in lifting heavy loads. Poyamba, ife tinakayikira nkhani yothandiza ndipo tinaitanidwa muukadaulo kuti ayang'anire. Komabe, titazindikira mwatsatanetsatane, tinazindikira kuti malo opangira mafuta mu hydraulic dongosolo anali otsika kwambiri.

Ndinazindikira za chochitikachi, ndinazindikira kuti tinanyalanyaza kufunikira kwa kukonza mafuta nthawi zonse. Ngakhale anali ndi ndandanda yokonza, zinali zosavuta kuphonya zizindikiro za kuwonongeka kwa mafuta, makamaka pa nthawi yotanganidwa. This oversight not only led to unexpected downtime but also incurred additional repair costs that could have been avoided with proper maintenance.

Izi zidachitika ngati phunziro lofunika kwambiri kwa gulu lathu, ndikugogomezera udindo wovuta wopanga. Kuyambira nthawi imeneyo, takhazikitsa ma protocol osamalira mafuta, kuphatikizapo macheke okhazikika a mafuta am'madzi okhazikika. Mwa kukhalabe maso ndi kukhala otopa, takwanitsa kupewetsa zochitika ngati izi ndikuwonetsetsa kuti mwachitapo zokhudzana ndi malo athu.

Post Nthawi: Mar-27-2024